Before using any care assistance equipment, "inspection" is a crucial and indispensable step.

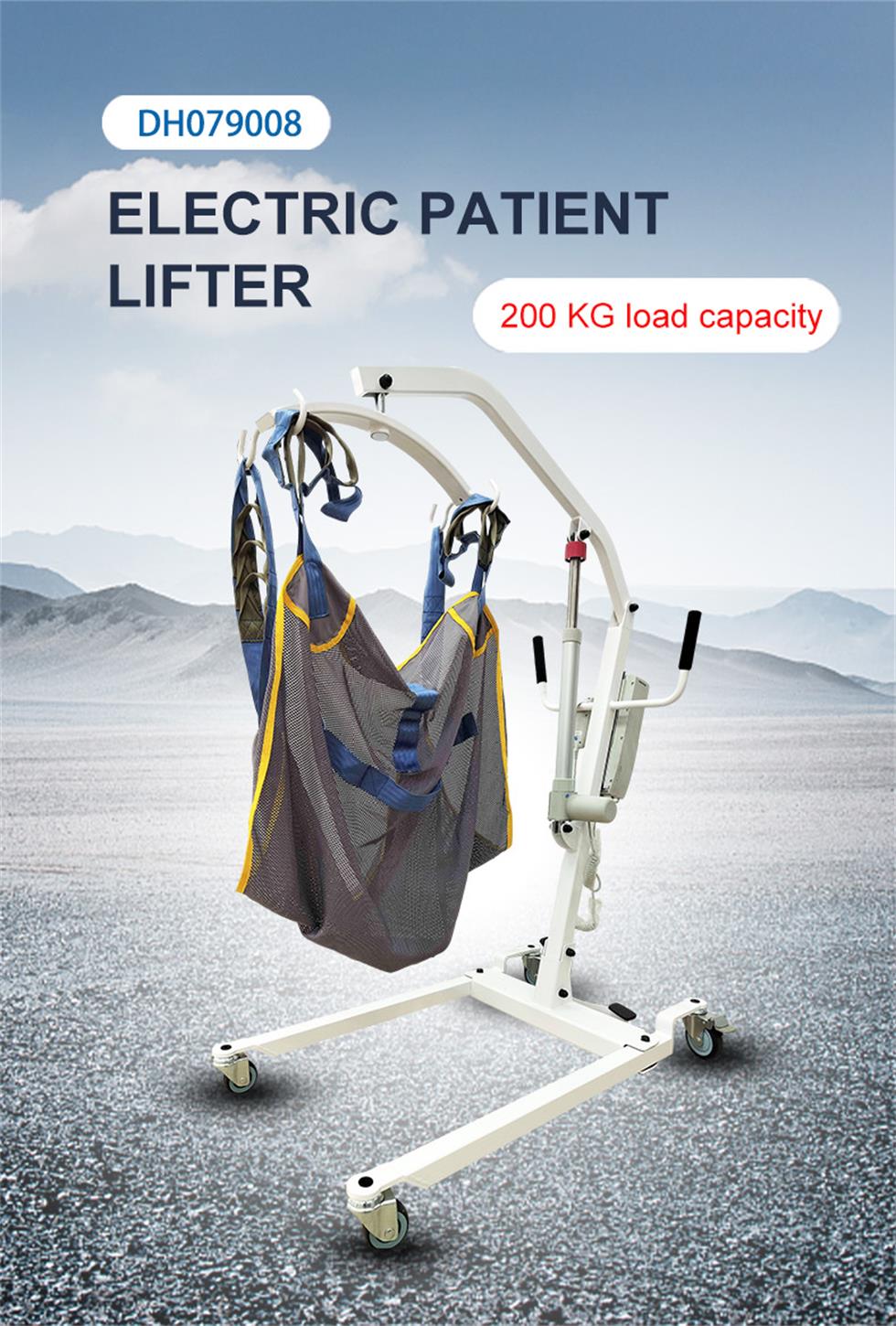

For equipment like the Patient Transfer Lifter, which directly relates to the safety of both the patient and the caregiver, pre-use inspection is an essential step.

Many transfer risks do not stem from quality problems with the equipment itself, but rather from inadequate pre-use inspections.

Therefore, it is especially important to clarify the following questions:

What exactly needs to be checked before using a Patient Transfer Lifter? Why can't these checks be omitted?

This article will systematically explain the key aspects that must be checked before using a Patient Transfer Lifter, helping you establish a standard and professional inspection approach.

Why is inspection necessary before using a Patient Transfer Lifter?

Where do the risks of using a Patient Transfer Lifter come from?

The Patient Transfer Lifter involves the following high-risk actions during use:

• Lifting the patient

• Suspended weight bearing

• Moving the patient

• Precise placement

A problem in any of these steps can lead to serious consequences. Therefore, pre-use inspection is the first line of defense against risks.

What is the core purpose of pre-use inspection?

The main purposes of inspecting the Patient Transfer Lifter are:

• To confirm that the equipment is in a safe and usable state

• To identify potential hazards and avoid them in a timely manner

• To ensure that the weight capacity and structure are matched

• To prevent sudden malfunctions during operation

What should be checked first before using a Patient Transfer Lifter?

Should the overall structure be checked first?

Yes.

Checking the overall structure is the first and most basic step before using a Patient Transfer Lifter.

Key areas to observe include:

• Whether the frame has any obvious deformation

• Whether the support structure is intact

• Whether the welded parts are secure

• Whether there are any cracks or looseness

During weight bearing and lifting, the structural integrity of the Patient Transfer Lifter directly determines safety.

Why can't overall structural problems be ignored?

If the structure of the Patient Transfer Lifter has hidden dangers, it may lead to:

• Unstable center of gravity

• Abnormal structural stress

• Equipment tipping over

Therefore, any visible structural abnormalities should prevent further use.

Does the weight capacity of the Patient Transfer Lifter need to be checked?

Why is weight capacity inspection so important?

Weight capacity is one of the most critical safety parameters of the Patient Transfer Lifter.

Each Patient Transfer Lifter has clearly defined:

• Maximum weight limit

• Designed safe working load

Before use, it must be confirmed that:

• The patient's weight is within the weight limit

• The weight of the sling and accessories has been considered

What are the consequences of neglecting weight capacity checks?

If the Patient Transfer Lifter is overloaded, it may lead to:

• Equipment imbalance

• Structural damage

• Lifter tipping over

Therefore, weight capacity checking is a crucial and indispensable inspection item.

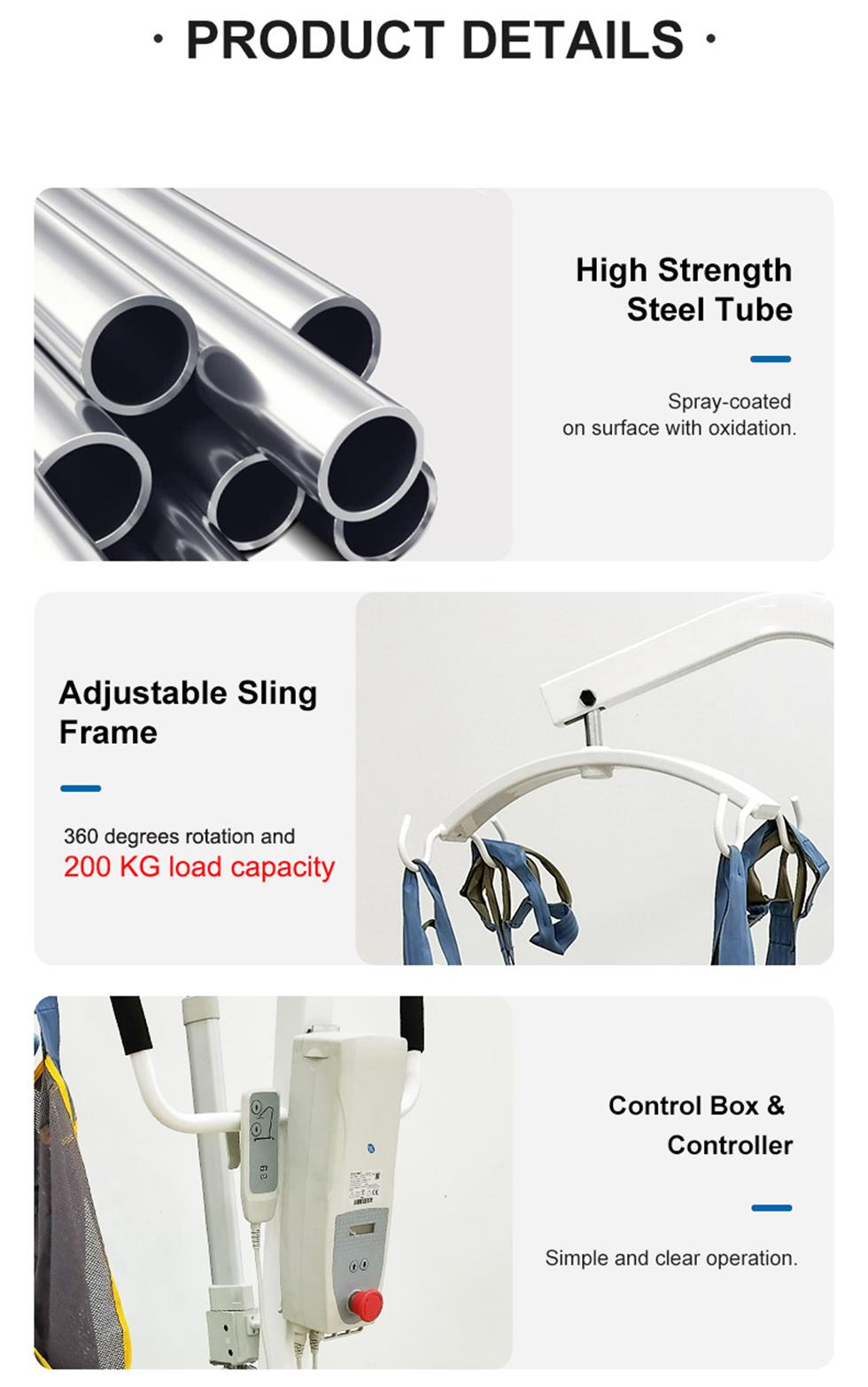

Do the slings need to be inspected before using the Patient Transfer Lifter?

Is sling inspection a key point?

Absolutely.

The sling is a critical component of the Patient Transfer Lifter that directly supports the patient's body.

Before use, check:

• Whether the sling is damaged

• Whether there is obvious wear and tear

• Whether the stitching is intact

• Whether the material is aging

Why is the condition of the sling so critical?

If the sling fails during the transfer process, it will directly cause the patient to lose support, posing a very high risk.

Therefore, any sling with:

• Tears

• Thinning

• Deformation

should not be used.

Do the connection points of the Patient Transfer Lifter need to be inspected?

Which connection points need to be checked carefully?

Before using the Patient Transfer Lifter, the following should be checked:

• The connection point between the sling and the hook

• The connection between the hook and the crossbar

• The locking status of removable parts

Ensure that all connection points are:

• Correctly installed

• Fully locked

• Free from the risk of loosening

What are the potential hazards of loose connections?

Loose connection points may lead to:

• Sling detachment

• Patient positional imbalance

• Sudden slippage

Therefore, connection inspection is a necessary condition for the safe use of the Patient Transfer Lifter.

Does the lifting system of the Patient Transfer Lifter need to be inspected?

Does the lifting system need to be confirmed in advance?

Yes.

Whether it is a manual, hydraulic, or electric Patient Transfer Lifter, the lifting system must be inspected before use.

The inspection includes:

• Whether the lifting is smooth

• Whether there is any abnormal jamming

• Whether there are any unusual noises

What does an abnormal lifting system indicate?

If abnormalities occur during the lifting and lowering process, it may indicate:

• Internal component wear

• Hydraulic system problems

• Mechanical transmission malfunction

In this case, the Patient Transfer Lifter should not be used for lifting operations.

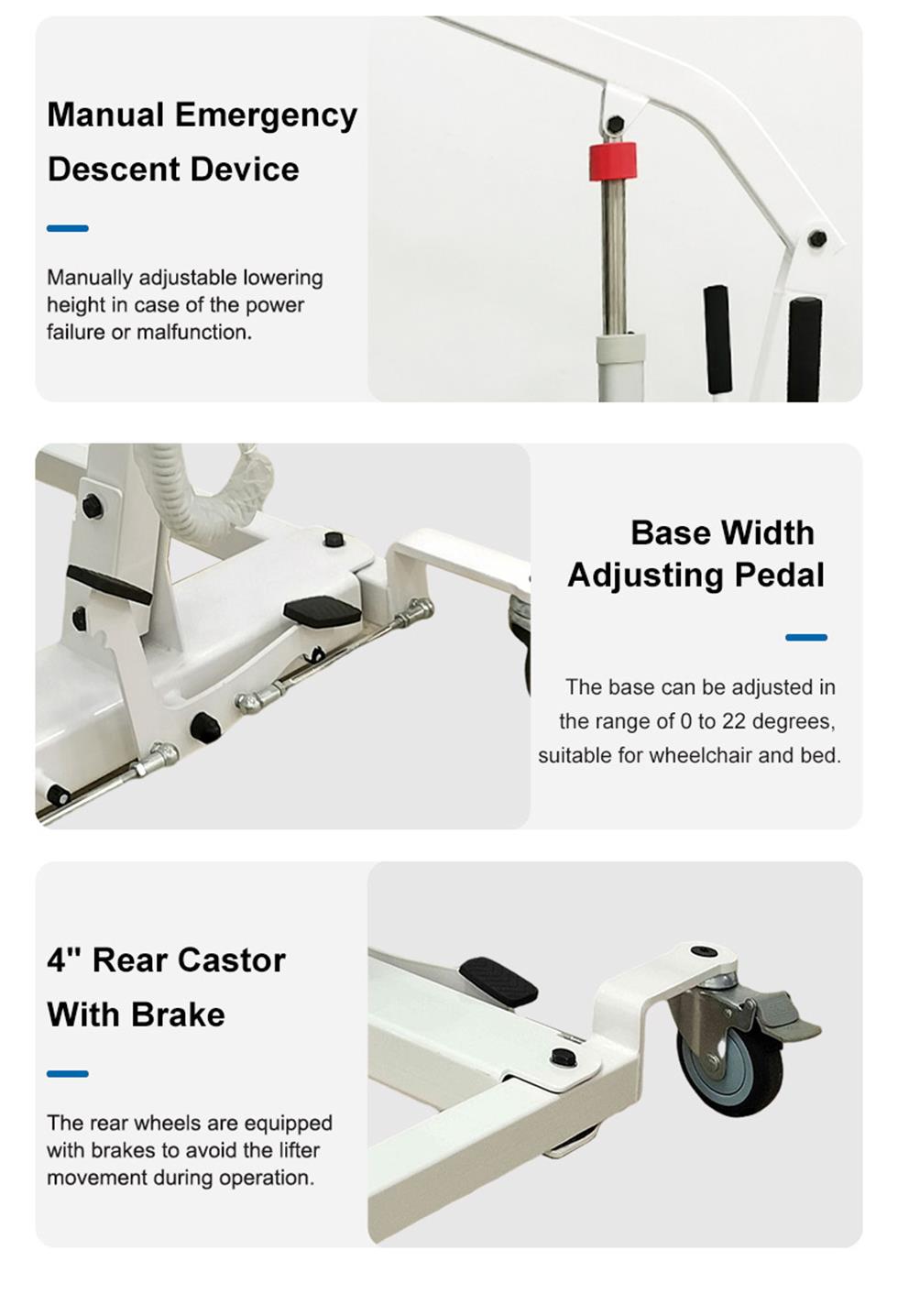

Do the moving parts of the Patient Transfer Lifter need to be inspected?

Do the wheels and base need to be inspected?

Yes.

The Patient Transfer Lifter needs to move during the transfer process, therefore:

• Whether the wheels are flexible

• Whether the wheels are jammed

• Whether the brakes are effective

These are all essential items to check.

Why is the braking function crucial?

When lifting and placing patients, if the brakes fail, the Patient Transfer Lifter may:

• Slide

• Shift

• Lose its position

This significantly increases the risk of injury during transfer.

Do safety devices need to be checked before using the Patient Transfer Lifter?

What safety devices does the Patient Transfer Lifter have?

Common safety devices include:

• Safety locks

• Limit devices

• Anti-detachment structures

Before use, these devices should be confirmed to be in normal working order.

What are the consequences of safety device failure?

Safety devices are designed to prevent:

• Excessive lifting or lowering

• Accidental unhooking

• Sudden loss of control

If the safety devices are not working properly, the Patient Transfer Lifter should be taken out of service.

Does the environment need to be checked before using the Patient Transfer Lifter?

Does the usage environment affect the safety of the Patient Transfer Lifter?

Yes.

The Patient Transfer Lifter has certain requirements for the operating environment.

Before use, you should check:

• Whether the ground is level

• Whether there are obstacles

• Whether there is enough space for operation

Why is environmental inspection important?

A poor environment can lead to:

• The transfer lift being unable to move smoothly

• Limited operating space

• Accidental collisions or jamming

Environmental inspection is an important part of the overall safety check.

Do you need to confirm the patient's condition before using the Patient Transfer Lifter?

Is the patient's condition also part of the inspection?

Yes.

Before using the Patient Transfer Lifter, you should confirm:

• Whether the patient's posture is suitable for sling support

• Whether there is any obvious discomfort

• Whether the patient can cooperate with the operation

Although this is not a device inspection, it is an important prerequisite for safe use.

How to establish a standard pre-use inspection process for the Patient Transfer Lifter?

Is there a clear inspection sequence?

The following logic can be followed:

1. Check the overall structure of the Patient Transfer Lifter.

2. Confirm the weight capacity.

3. Check the condition of the sling.

4. Confirm that the connecting parts are secure.

5. Test the lifting system.

6. Check the wheels and brakes.

7. Check the safety devices.

8. Confirm the operating environment.

Checking in this order helps to avoid omissions.

What are Dahao Medical’s delivery timelines for bulk orders?

The delivery timeline for bulk orders from Dahao Medical depends on factors such as order size, product specifications, and shipping destination. Generally, bulk orders are processed and shipped within 4 to 6 weeks. We prioritize fast, reliable delivery and ensure that all products are shipped with care to prevent any damage during transit.

For urgent orders, we offer expedited shipping options to meet tight deadlines. Please contact our sales team for specific lead time estimates based on your order.